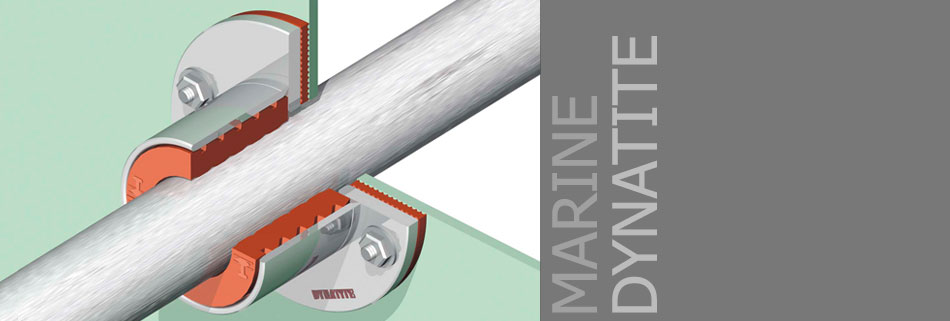

The DYNATITE sealing plugs were developed for applications where a high degree of (instantaneous) tightness is required. The DYNATITE plugs are compressible;the high-tech design of DYNATITE actually allows the system to get tighter as the pressure increases.

Applications

The plugs can easily withstand shock pressure loads of more than 150 psi (10 bar) and will return to their original shape after shock pressure. The dynamic compression of the plug is based on the high-tech rubber grade and the engineered profiling.

DYNATITE was specially developed for application in columns in semi-submersible offshore rigs, following incidents where traditional cable transit systems suffered catastrophic failure under high pressure.

Today's typical application areas of the DYNATITE system are:

- columns of offshore oil rigs

- environments where penetrations may be suddenly exposed to extreme conditions

- partitions between hazardous and non-hazardous areas

- blast walls

- explosion-proof areas

- regions with elevated hurricane and tsunami risks

Features

- For applications where a high degree of (instantaneous) tightness is required

- Dynamic sealing when a disaster occurs

- Plugs are compressible and will return to their original shape after shock pressure

- Easily withstands shock pressure loads up to 15 bar (220 psi)

- Ideal solution for cable and pipe transits in subsea and explosion proof installations

- Breakthrough - dynamic compression

- Based on high-tech rubber grade and engineered profiling, the DYNATITE plugs can be substantially compressed and get tighter with excessive pressure